Paper Mills Press On With AI Visual Inspection

Over hundreds of years, paper products have been commoditized so much that the industry average profit margin is in the low- to mid-single digits. Meanwhile, findings show that the estimated average cost of unplanned downtime for a paper or pulp plant is $220,000 per day.

In short, paper suppliers can’t afford faulty equipment. That’s why they’re using AI-enabled visual inspection to guard against complications like wet line—excess water from the pulpy mixture that’s mechanically pressed to make paper.

If it makes its way too deep into the press machinery, wet line can destroy drying paper and stop the production process itself.

The phenomenon occurs organically during the process of flattening watery pulp, so it can’t be eliminated entirely. Still, it needs to be monitored, which itself can be a challenge. Today, press operators climb ladders on the side of machinery because the water line is often visible only from acute angles. If it has progressed too far, the equipment must be readjusted from a nearby headbox, and possibly even cleaned.

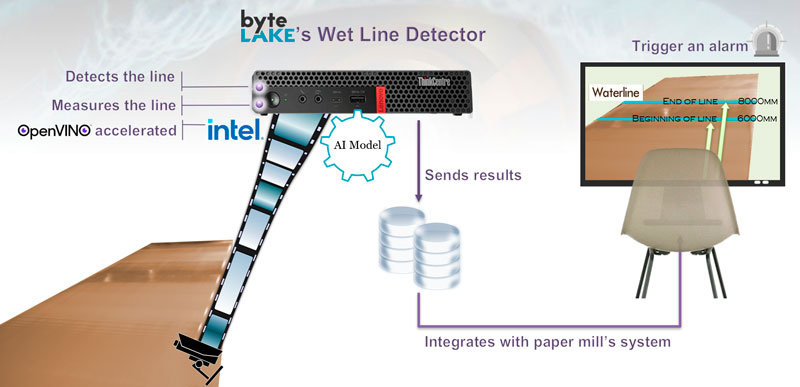

AI-based computer vision can automate this process to keep presses running and wet line in check. And this isn’t some futuristic proof of concept, either. byteLAKE, a company specializing in AI-enabled visual inspection and big data analytics for manufacturing, has already deployed its Cognitive Services platform at a major European paper mill.

Paper suppliers can’t afford faulty equipment. That’s why they’re using #AI-enabled visual inspection to guard against complications like wet line. @byteLAKEglobal via @insightdottech

AI on Paper

byteLAKE’s Cognitive Services is an end-to-end IT/OT platform that performs tasks traditionally done by humans. But while further automating an automated process sounds easy, there were still specific requirements byteLAKE engineers had to meet before implementing their solution at the mill. These included plant operators’ desire to keep:

- Press machinery unaffected

- Production processes intact

- Deployment costs to a minimum

These requirements immediately ruled out monitoring solutions based on conventional moisture sensors or flow meters. At the same time, they also demanded sophisticated analytics and edge processing capabilities that could keep operators from being overwhelmed by sensor data.

byteLAKE proceeded to install high-resolution cameras with an unimpeded view of wet line on the plant’s presses. Images are transmitted to an edge computing platform where a version of the YOLO real-time object recognition algorithm combined with byteLAKE’s AI models determine whether wet line has crept beyond predefined boundaries.

From there, images and metadata are sent to plant management software that can alert operators or trigger commands to adjust pulp composition or increase the power of drying fans (Figure 1).

Data then continues into IT systems where the Cognitive Services platform applies analytics so that operators can tune their press machinery and plant processes to operate more efficiently in the future.

From Months to Automatic

Besides the complex system integration challenges of new and existing IT and OT platforms, byteLAKE spent considerable energy constructing a data set of paper press and wet-line images to train their object detection model. Then they had to optimize the on-premises hardware so it could effectively execute their new algorithm. This started by evaluating an Intel® Core™ i5-based edge computing solution.

Intel Core processors are more cost-effective and power-efficient than the alternative. And in the case of wet line analytics, they can deliver a competitive 12 frames per second (FPS) of image processing thanks to a 10x boost in neural network execution provided by the Intel® OpenVINO™ Toolkit, a development suite that tweaks AI algorithms to run as optimally as possible on Intel® CPUs, FPGAs, GPUs, and accelerators.

“You can do it manually and spend many months, or you can leverage YOLO and OpenVINO, which can go through your product, inspect the architecture, and eventually give you a 10x speed up,” says Marcin Rojek, byteLAKE’s co-founder.

AI-Assisted Papermaking: The Writing Is on the Wall

The byteLAKE Wet Line Detector (part of byteLAKE’s Cognitive Services) deployment is one of the first cases of AI adoption in the paper industry, but it certainly won’t be the last. Because wet-line monitoring requires only a couple of images each minute, the system’s 12 FPS leaves more than enough headroom to perform wet line detection for an entire plant on the same edge hardware.

And byteLAKE is also developing solutions that go beyond the paper mill, deploying AI in use cases like computational fluid dynamics (CFD). According to Rojek, the company is currently using deep learning to reduce CFD simulations for liquids from more than four hours to less than 10 minutes, all while retaining better than 93% accuracy. The product—CFD Suite—is available for the chemical industry.

“In many cases, the technology has matured enough that nowadays it is relatively easy to leverage various building blocks of AI for the solution we need,” he asserts.

We’ll see only more of smart-factory, AI-based solutions like these, especially where margins are paper thin.