Turnkey AI From Development Kit to Deployment

In 2017, work-related injuries cost insurance companies an estimated $161 billion. And of course the impact on workers’ health and safety goes beyond the numbers. That’s why many worksites require protective gear such as helmets, vests, gloves, and masks. But enforcing these policies can be a challenge. It’s not always practical to keep staff on hand to monitor workers. Some worksites are too remote, have too many different work areas, or have unpredictable work hours.

So how can better worker safety be achieved?

AI Vision Is the Smart Answer

With the advancement of artificial intelligence (AI) and computer vision technologies, a better solution has emerged.

As illustrated in Video 1, safety enforcement can be automated via computer vision. Workers must wear required protective gear before gaining entrance to restricted areas. The system also uses facial recognition to ensure that only qualified personnel access the site.

Video 1. Computer vision can enforce protective gear policies.

But developers and solution integrators face challenges when deploying such a system. Significant resources and tools are needed to develop AI on edge platforms. And implementing machine learning can be complicated and time-consuming.

AI systems can require thousands of images to learn the appropriate objects or actions needed for real-time analysis and response.

Streamline Computer Vision and AI Deployments

UP ! Bridge the Gap, a division of AAEON Technology, has created an AI Vision Development Kit to help developers and solution integrators quickly implement and deploy computer vision solutions.The kit is a proven, ready-to-go solution that includes everything needed to start an AI project.

Plus, it provides a pre-trained solution designed specifically for industrial safety applications with the idea of providing a demo system right out of the box.

“The UP AI Safety Development Kit is a turnkey solution so developers can provide customers a proof of concept right away,” said Aling Wu, AAEON IoT Alliance Director. “And for those who would like to do further AI development, we provide the tools needed to make their job easier.”

Out-of-the-Box AI

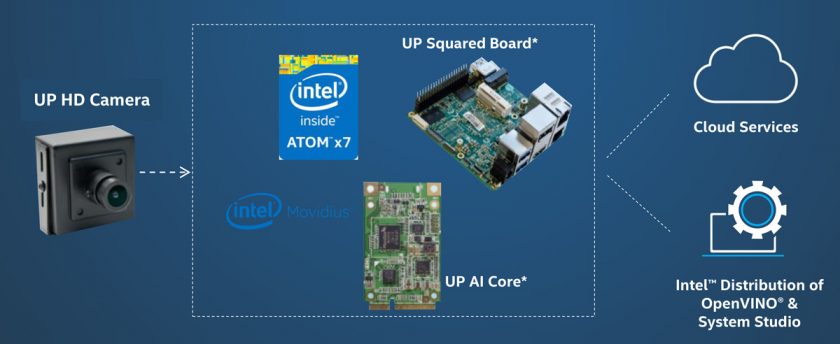

As shown in Figure 2, the kit consists of Intel®-based hardware in a compact aluminum chassis unit, along with a USB HD camera. The included AI software is pre-trained to recognize helmets, vests, gloves, and masks in a variety of shapes, colors, and forms.

The hardware comprises two boards. The base platform is built around an Intel Atom® processor. An add-in card, the UP AI Core X, provides plug-in acceleration of inference workloads using an Intel® Movidius™ Myriad™ processor. Together these modules give developers options for deploying AI with different hardware configurations as the application demands.

Optimized for a variety of industrial applications, the solution includes the system and software tools needed to get to work quickly:

- Pre-installed Ubuntu OS

- Intel® Media SDK

- Intel® OpenVINO™ Toolkit

- Intel System Studio

- Cloud-based Arduino Create IDE

“A developer or solution integrator can get all the tools from Intel and other ecosystem partners. But to develop a computer vision solution with AI and deep learning takes time, effort, and expertise,” said Aling Wu. “For those who don’t know too much about AI, this solution is perfect for them to get started.”

It Takes a Community

UP is the brand for professional “makers” and “innovators”. The UP Garage Team is a group of independent hardware and software engineers building solutions to bridge the gap between a makers’ market and the standard industrial and embedded market.

With shared ideas and experiences, they are creating something unique: merging in one board the benefits of Intel technology with the benefits of “makers” form factors.

There’s more to learn about the UP Squared AI Vision X Developer Kit at the Intel Developer Zone.