The IIoT Powers Smart Grid Substations

As more devices join the IIoT, more energy is needed to power them. And while this is putting more pressure on the electrical grid, it’s also introducing new methods of intelligently powering the world.

IIoT technologies can accelerate smart grid automation and deliver unprecedented energy optimization. For example, substation applications like predictive load monitoring, pre-emptive switching, and high-accuracy voltage transformation can generate new levels of efficiency and uptime.

But adding IoT connectivity and analytics to the power grid can be risky. There is the capital expense of compute and networking equipment. Security vulnerabilities can increase. And there is always the possibility of interoperability issues between new and legacy systems.

New electronic system designs are emerging that balance the reliability, interoperability, and cost concerns of the energy industry. These systems are primarily based on the concept of workload consolidation.

But before addressing workload consolidation, let’s consider the function and architecture of a typical substation.

Standards Set the Table For Automation

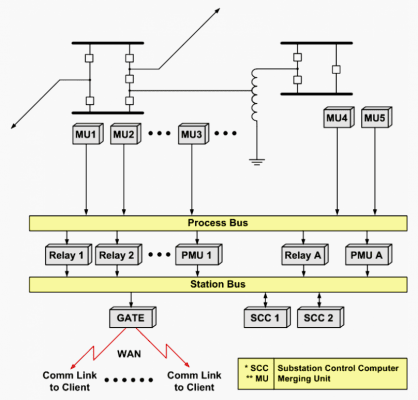

Electrical substations are responsible for collection, conversion, transmission, and/or distribution of power from an energy source. They rely on devices called merging units (MUs) that sample and digitize analog currents coming off transformers (Figure 1).

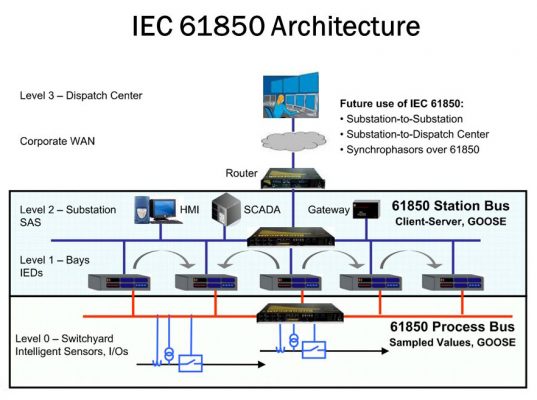

MUs are also the first node in substation communications networks. Many of these networks are based on the IEEE 61850 standard, which supports multiple protocols for transmitting digital signals among power subsystems from different vendors. They also carry information out to HMI platforms and SCADA networks over industrial Ethernet (Figure 2).

IEC 61850 networks provide latencies of less than four milliseconds for real-time signaling among substation nodes. These protocols also support abstract data models and reporting schemes that are compatible with enterprise systems.

This hybrid IT and OT networking capability means that a single IEC 61850-enabled gateway platform can perform both embedded control and enterprise data analytics.

This is where workload consolidation comes in.

Reduced Cost and Increased Intelligence

Workload consolidation is based on multicore processors and virtualization technology.

Virtualization enables the use of real-time, safety-critical hypervisors that securely isolate data and processes to a specific processor core or cores. Hypervisors can also contain breaches, faults, and vulnerabilities to those cores so that critical functions can continue even if an enterprise application goes down.

For more information on workload consolidation, read Embedded Virtualization Powers Mixed-Criticality IoT Systems.

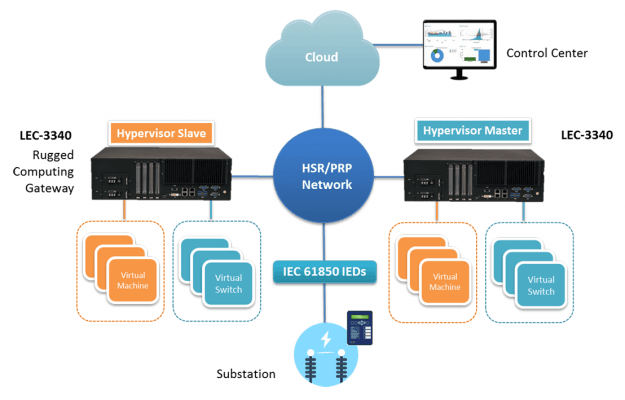

In mixed-criticality gateways, this means that OT workloads like voltage transformation can run side by side with analytics applications such as predictive load management (Figure 3).

Another benefit of virtualization technology is redundant system design. In a four-core system, two cores could be dedicated to running virtual network switches that route traffic across the OT/IT network boundary. The other two cores could be dedicated to data acquisition, with one core executing the primary workload and the second providing application redundancy.

In all, workload consolidation checks a lot of boxes for energy system designers:

Reliability. Deploying predictive monitoring, switching, and other analytics-based applications on-premises can boost substation uptime and efficiency. In the short term, it can help avoid the negative effects of power surges and voltage spikes. Over the long term, it protects equipment from the wear and tear of damaging events.

Security. Subdividing platforms into robust partitions means that applications exposed to lower-integrity networks can be isolated from the rest of the system. This can help guard against malware or threats that originate in corporate/IT environments, as was the case in the 2015 cyberattack on the Ukrainian power grid.

Cost. Integrating multiple functions onto a single platform provides immediate CAPEX savings. It also makes the overall infrastructure easier to manage. And improved reliability can provide significant savings over the lifecycle of electrical substations as well.

Rugged and Reliable Smart Grid Automation

A specific type of multicore processor is needed to maximize the benefits of workload consolidation. In substation automation gateways, this processor must be powerful enough to facilitate high-bandwidth networking and analytics while also being rugged and deterministic.

A form, fit, and function match for workload-consolidated substation automation gateways is the Intel® Xeon® E3-1500 processor family. Quad-core Xeon E3-1500 processors provide eight threads of performance but maintain a thermal design power (TDP) of just 25 W. They are also available in embedded options that assure extended lifecycle support and availability.

The E3-1500 series processors integrate enterprise features like Intel® Virtualization Technology (Intel® VT-x) and Intel® Active Management Technology (Intel® AMT). This rare combination of performance, reliability, and manageability provide all the basic building blocks for workload consolidation on substation gateways.

To bring the E3-1500 into smart grid settings, Lanner Electronics Inc. has developed the LEC-3340, an IEC 61850 and IEEE 1613-compliant 3U rackmount controller system, designed for high-reliability and high-availability substation automation (Figure 4).

The Lanner gateway includes redundant AC/DC power supplies (16.6 to 160 VDC/100 to 240 VAC) that help maximize platform reliability. The systems also include two hot-swappable 2.5” drive bays.

The drive bays can be used to support additional power supply units that make the platform useful as a battery backup bank. Alternatively, they can be used to support SSD RAID storage for improved data resiliency. And since they are hot-swappable, they can be changed without having to power down the system.

Taking reliability and availability to the extreme, the platforms support optional High-availability Seamless Redundancy (HSR) and Parallel Redundancy Protocol (PRP) cards.

“The LEC-3340 is designed as an expandable platform, with PCI expansion and a virtualization-ready processor,” said Brian Chen, Marketing Manager at Lanner Electronics Inc. “Depending on where the appliance is being deployed, it can support PCI modules for different connectivity purposes, like HSR and PRP module cards for network failover in a power station.”

ESD surge protection, ECC memory, and an optional trusted platform module (TPM) 2.0 round out the platform reliability highlights.

Artificially Intelligent Automation?

Workload consolidation and high-performance processors also open the door for AI and machine learning to deploy locally at substations. Running on a platform like the LEC-3340, the operating conditions of an entire substation could be analyzed in real time for optimization purposes.

Short incoming spikes or drops in voltage that reduce conversion efficiency could be analyzed instantaneously. And certain currents could be switched to specific transformers optimized to handle those specific voltage levels.

With high-performance workload consolidated, this future is more attainable than you’d think.