Computer Vision, AI Put Remote Assets in Focus

For IIoT engineers, remote asset monitoring is both a gift and a curse. On the one hand, it can inform on the condition of field equipment hours, days, or even weeks earlier than traditional maintenance routines. It can also ensure that the right personnel are deployed to the right locations at the right time.

Remote operators can determine the cause of a perimeter breach or analyze a situation reported by another analog sensor in a matter of moments. With the right technology, they can even determine the source of a gas leak, what types of gas are being released into the atmosphere, and how many cubic meters are being released per second.

But on the other hand, this all comes with a cost.

On-Premises Analytics Changes the Game

If a picture is worth 1,000 words, it would appear that a video stream is worth $400. Why? Because that’s about how much a monthly cellular data plan costs for a single surveillance camera.

That really stings, for a variety of reasons, but mostly because these sites often require multiple cameras, and only a minuscule amount of the video they produce has value. Consider an oil field with 1,000 well sites, for example. The connectivity costs are massive.

Fortunately, more intelligent ways of deploying video surveillance technology are available. For example, rather than having every camera installed at a multi-camera site transmit video over its own cellular connection, why not route them all through a single on-premises server? And instead of streaming full-blown video files, why not leverage analytics to identify specific clips that should be sent?

These are innovations that Pixel Velocity uses with its Event Velocity software platform.

“Video is a bandwidth pig, and creates all types of problems,” said Jonathan Murray, CEO of Pixel Velocity. “And 99 percent of the video is inert—nothing happens.” Event Velocity processes video at the edge and sends only metadata over the telecom network to generate alerts.

“These alerts are just a clip of video. Then an operator can choose to look at the site in real time. And we can get them into a data plan that’s $55 per month for an entire site because the cellular connection is through a server, and multiple cameras can connect there,” said Murray.

“Video is a bandwidth pig, and creates all types of problems. And 99 percent of the video is inert—nothing happens.”—Jonathan Murray, CEO @Pixel_Velocity

Fewer Truck Rolls with Real-Time Monitoring

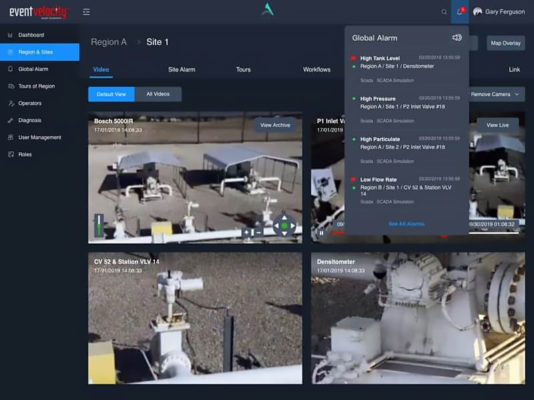

Event Velocity leverages the OPC-UA communications standard to integrate data from multiple types of IoT sensors, including audio, infrared, SCADA systems, and, of course, video. The technology combines data from these devices to generate automated alerts about unforeseen events, applying intelligent video analytics to minimize false positives and reduce alert fatigue or unnecessary truck rolls.

Users can configure the platform to look for specific variables or event triggers, such as activity in exclusion zones or temperature fluctuations in certain areas. The monitoring solution also integrates optical gas imaging software that, when paired with a compatible imaging sensor, can detect 22 different hydrocarbons. This imaging software analyzes variables like plume composition, size, and shape, and overlays video with green, yellow, and red indicators to help operators interpret potentially dangerous environments more quickly.

If an analog sensor trips, Event Velocity automatically trains a camera on the asset and analyzes the resulting video feed to determine whether the reading is legitimate. The platform leverages a distributed computing model so that this analytics processing is performed on Intel® processor-based systems like the Dell Edge Gateway, which can support up to seven simultaneous video streams.

If a situation is benign, Event Velocity stores video on these local edge servers for a designated period of time and transmits only periodic metadata for historical reporting purposes. But if the system determines an event as being of possible interest to operators, a small video clip can be sent to the cloud.

Here, an integrated message management system ensures that alerts are communicated to the appropriate stakeholders via mobile messages, email, or web clients. Once operators receive an alert, they can view the clip, and tap into a live video feed of the asset if necessary (Figure 1).

All of this occurs in real time, providing the highest-possible visibility to users at the lowest cost possible. And because Event Velocity is built on top of OPC-UA and other open APIs, it can be easily integrated with existing control or SCADA installations and enterprise infrastructure.

An Eye for Remote Intelligence

With advanced video surveillance, IIoT operators can leverage video analytics technologies that automate the filtering of alerts. What’s more, engineers can then use that same video infrastructure to zoom in on the real-time status of remote assets and gain nearly the same insights as if they were on scene.

Now that IIoT edge computing and analytics software solutions can deliver these capabilities at economical price points, not using video-based asset monitoring could actually be costing you productivity, efficiency, and more.