AI Technology Transforms Supply Chain Operations

Supply chain operators have always been tasked with keeping goods flowing from the warehouse to the customer. While getting things from point A to point B sounds straightforward enough, unforeseen conditions can impact the process.

Around the globe we’re experiencing especially challenging times. For one, there’s an unprecedented need to quickly procure and transport personal protective equipment (PPE) to hospitals and first responders. And keeping store shelves stocked with food and supplies has tested the supply chain from factories and farms to grocers’ receiving docks, and everywhere in between.

An industry already challenged to meet deadlines and quality standards has quickly found itself in the spotlight, with intense pressure to perform, highlighting long-held practices that were due for a change. Innovative technologies are making it possible to tackle such challenges—today and into the future.

For logistics and supply chain operators, knowing more about the status of their products allows them to deliver better service to their customers. It can also help with internal processes, such as quality control, and reduce costs within their own organizations.

Flexible IoT solutions can automate supply chain management in real time and ensure that materials and products are kept safe every step of the way. But the industry has been slow to embrace the AI technology that can help it improve.

“Operators know logistics and supply chain really well, but making the leap across the chasm into some type of digital transformation program is a challenge,” said Roland Ducote, Supplier Management Director for global solution aggregator Arrow Electronics. “Many simply don’t have the resources to support those solutions or ideas.”

In addition, logistics supply chain operators often have time-honored systems for warehouse and operations management. Disrupting a process that has been in place for decades can feel overwhelming.

“It’s much more than just attaching sensors and gateways,” said Ducote. “It’s connecting them to operational data for a full integration into their systems.”

“It’s much more than just attaching sensors and gateways. It’s connecting them to operational data for a full integration into their systems.” —Roland Ducote, @ArrowGlobal

Supply Chain Management Solutions

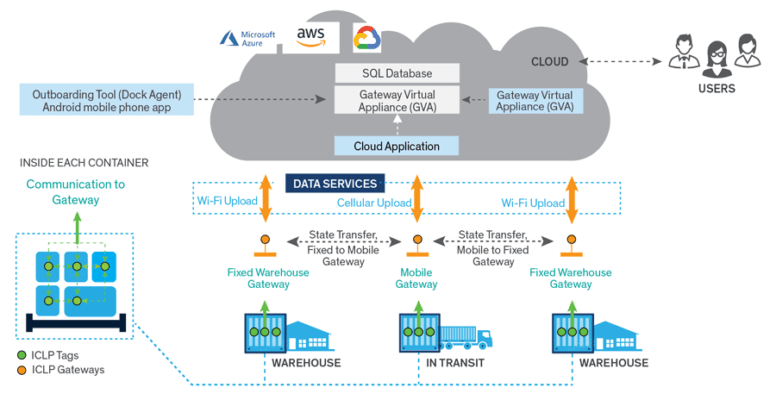

While the transformation can be complex, the supply chain’s challenges are important to solve. Nearly $23 billion worth of global shipments are damaged, delayed, or lost every year. And 30 percent of perishable goods spoil before they reach their destination. Systems integrators (SIs) can help operators improve operations by leveraging and deploying AI technology. And end-to-end solutions, such as the Arrow Electronics Inc. Intel® Connected Logistics Platform on Azure, can simplify the process (Figure 1).

“SIs want to focus on customer applications and outcomes,” said Ducote. “Our role is to deliver hardware and software components bundled together that work for organizations and get through proof of concept. We provide a reference architecture so that SIs can get up and running quickly.”

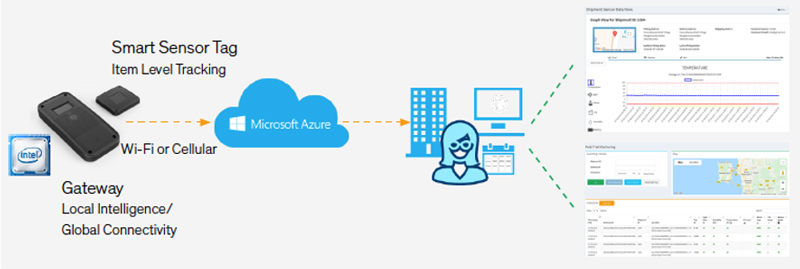

Integrators have two paths to choose from. Azure IoT Hub allows SIs to select and build custom solutions, while Azure IoT Central is a solution accelerator and full SaaS offering that’s ready off the shelf. Solutions combine smart sensor tags and gateways that track shipments throughout the supply chain and provide real-time alerts and insights about an asset’s location, condition, and security on the customer dashboard (Figure 2).

The solution is also sustainable. Gateways are rechargeable and the tags are reusable. “You’re not adding to waste,” said Ducote. “The tags are hardened and ruggedized, with a replaceable coin cell battery.”

With many shipments going around the world, Arrow also solves the connection challenge. “Getting device data moving to the cloud requires resources and expertise,” said Ducote. “What we’ve done to address this challenge is to bring together the hardware and cloud platform for systems integrators to immediately start development.”

AI Technology on the Road

One of Arrow’s clients was an SI working with a pharma company to gain end-to-end efficiencies in delivery of medication sensitive to light, humidity, temperature, and motion.

“We built a very specific cold chain use case around the environment,” said Ducote. “It could show that the device did not reach critical thresholds around shock and vibration, and was always kept at a refrigerated temperature. This is a huge value proposition for logistics and supply chain operators to provide back to organizations for quality control or tracking.”

Another SI client was serving a logistics and shipping customer that needed to transport large construction equipment. The challenge was delivering high-value assets to remote locations. “Believe it or not, even things the size of buses can get lost,” said Ducote.

Arrow worked with a systems integrator to build a multimodal asset-tracking solution that provided GPS data and precise estimates on delivery time.

“In enterprise or commercial environments, having the right equipment at the right time is absolutely critical,” said Ducote. “Companies would bring in workers. If the equipment doesn’t show up, they still have to pay those workers and they lose money. By scheduling a crew when the equipment is available, they best utilize their assets.”

Large and small, supply chain operators move a wide variety of goods, but their main concerns are the same.

“Organizations aren’t just asking, ‘Where are my assets?’ They want to know, ‘What are my assets doing?’” he said. “You’ve got high-value items that are traveling through a multimodal supply chain. They could be going from a factory to a truck to a plane to a truck to an end user like a hospital.”

With Arrow, SIs can quickly deploy proof of concept, getting to market faster. The company also offers a comprehensive set of tools, including hardware, software, SaaS, and even financing. Intel® is a key technology provider for Arrow.

“Our role is to take the amazing technology that Intel develops and build it into a solution that is usable by systems integrators and their end-user operators,” said Ducote. “Intel processors enable us to offer multiple use cases for multiple industries, and multiple transit routes. Organizations can identify problems, mitigate losses, reduce costs, and optimize their operations.”