Predictive Maintenance Keeps the Smart Factory Running

Time-based monitoring (TBM) has long been used to inspect and repair manufacturing equipment, but it’s no longer enough to compete in a modern, digital manufacturing world. Traditional TBM often leads to undetected equipment anomalies, downtime, and unexpected malfunctions. And TBM requires highly skilled personnel, who are becoming increasingly hard to find.

“As one of the key goals for digital transformation, business leaders are looking for ways to automate processes. To do so, it is necessary to detect any abnormalities in the factory machines on behalf of on-site workers,” says Daisuke Nishimura, Director, Global Innovation Office at Macnica, an IoT solution aggregator.

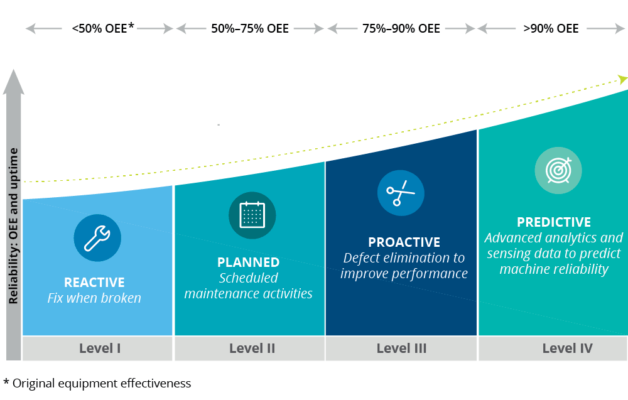

To prevent machine failures before they occur, manufacturers must start working toward a predictive maintenance approach (Figure 1). As a result, they are beginning the transition to condition-based monitoring (CBM) using sensor and AI-based technologies.

A Case for Condition-Based Monitoring

When a Japanese-based aerospace manufacturer began automating its assembly lines, it came across a major barrier. The perforation process relied heavily on highly experienced workers, making it too difficult to automate. The company set out on a mission to solve this issue using sensors and artificial intelligence (AI).

“To prevent fuel leak on aircrafts, there are strict requirements on the drilled hole quality,” says Nishimura. “If the hole doesn’t meet these criteria, the fix would be costly and require a significant amount of rework.” This meant that any abnormality of the perforating machines must not go undetected.

The company’s goal was to detect machine abnormalities using vibration sensor data. To do so, it teamed up with Macnica to implement sensors and collect condition data.

Condition-based monitoring is just one of the first steps into an autonomous #manufacturing future where innovations like edge #AI and #ComputerVision truly enable the #SmartFactory. @macnica_inc via @insightdottech

Macnica provided the SENSPIDER – Smart Sensor Gateway, which collects sensor data at the edge and uploads it to the cloud to power CBM services. “SENSPIDER can help system integrators work with customers on a wide range of devices and problems,” says Nishimura. “We do this by flexibly supporting optimal sensor deployment and preprocessing for each use case within a single box.”

While the project is still in progress, the team can now detect machine abnormalities in real time and are working on embedding the CBM feature onto their machines. This will allow the company to reduce its dependency on on-site workers and progress toward full assembly line automation.

New Opportunities with CBM-as-a-Service

“The impact of CBM is significant in production line automation, as equipment malfunctions can go unnoticed and lead to a pile of defective products,” says Nishimura. CBM also leads to new opportunities for systems integrators (SIs) and machine builders.

SIs can transform their business model by launching new features and services that leverage CBM. For example, they can remotely monitor equipment conditions and perform optimal maintenance for their customers. And they can provide advanced services with automated, AI-based alarms that notify if there are signs of abnormalities.

Machine makers who are looking to offer as-a-service solutions can also benefit from these capabilities. “The growing market demand for CBM has become a major factor that motivates machinery manufacturers to develop CBM as an added value,” Nishimura says. “It is difficult to expect dramatic improvements in individual machine performance. More and more manufacturers are starting to focus on improving services as a new differentiating factor.”

From PoC to Production

Implementing CBM is not without its challenges. According to Nishimura, manufacturers find it difficult to move beyond proof-of-concept (PoC) to production if the organization does not have a clear goal on what it is looking to obtain.

“It is important to determine whether the system is worth building and valuable for users by considering the cost of maintenance, the cost impact of equipment failure, and the benefits of improved productivity and quality before proceeding with the project,” Nishimura says.

Success also requires buy-in from upper management so that the project is allocated appropriate budget and resources to get off the ground. “This kind of problem often occurs if the project is not aligned with the company’s strategic plans and policies, or if it is not recognized as a worthwhile initiative,” Nishimura explains.

The technical challenges of CBM include selecting the right sensors, hardware costs for mass production and operation, and obtaining effective training data.

With a solution like SENSPIDER, SIs can incorporate customized functions, integrate with cloud environments, and accelerate development and deployment. It was designed to support a wide variety of analog sensors. And since it leverages Intel® SoC technology, Macnica is able to provide a high-performance platform at a lower cost than other solutions.

The company believes a five-phase approach to CBM development—which consists of building the sensing environment, performing simple data analysis, model iteration, PoC, and productization—is the best path to success.

“We recommend beginning with identifying the target machine type, building the sensor environment, and collecting the preliminary sensor data. This will help you run a quick initial iteration of data analysis,” says Nishimura.

Predictive Maintenance: Along the Path to the Smart Factory

Condition-based monitoring is just one of the first steps into an autonomous manufacturing future where innovations like edge AI and computer vision truly enable the smart factory. In addition to remote monitoring and predictive maintenance, the latest technologies can automatically tune equipment to best suit operating conditions.

Preventing machine abnormalities and degradation clearly helps manufacturers lower costs and improve profitability. Machine builders and SIs win, too. With as-a-service offerings they create a more sustainable and profitable business model.